-

K&S Metals K&S Bendable Brass Fuel Tube: 1/8" OD x 0.014" Wall x 12" Long $2.85

$3.99 -

K&S Metals K&S Brass Streamline : 1/4" OD x 0.014" Wall x 12" Long $3.07

$4.29 -

K&S Metals K&S Round Brass Tube: 1/16" OD x 0.014" Wall x 12" Long $2.22

$3.09 -

K&S Metals K&S Round Brass Tube: 1/2" OD x 0.014" Wall x 12" Long $3.57

$4.99 -

K&S Metals K&S Round Brass Tube: 1/4" OD x 0.014" Wall x 12" Long $2.14

$2.99 -

K&S Metals K&S Round Brass Tube: 1/8" OD x 0.014" Wall x 12" Long $1.43

$1.99 -

K&S Metals K&S Round Brass Tube: 11/32" OD x 0.014" Wall x 12" Long $3.57

$4.99 -

K&S Metals K&S Round Brass Tube: 13/32" OD x 0.014" Wall x 12" Long $3.64

$5.09 -

K&S Metals K&S Round Brass Tube: 15/32" OD x 0.014" Wall x 12" Long $4.28

$5.99 -

K&S Metals K&S Round Brass Tube: 17/32" OD x 0.014" Wall x 12" Long $3.70

$5.19 -

K&S Metals K&S Round Brass Tube: 19/32" OD x 0.014" Wall x 12" Long $4.99

$6.99 -

K&S Metals K&S Round Brass Tube: 21/32" OD x 0.014" Wall x 12" Long $5.49

$7.69 -

K&S Metals K&S Round Brass Tube: 3/16" OD x 0.014" Wall x 12" Long $1.57

$2.19 -

K&S Metals K&S Round Brass Tube: 3/32" OD x 0.014" Wall x 12" Long $2.57

$3.59 -

K&S Metals K&S Round Brass Tube: 3/8" OD x 0.014" Wall x 12" Long $2.99

$4.19 -

K&S Metals K&S Round Brass Tube: 5/16" OD x 0.014" Wall x 12" Long $2.35

$3.29 -

K&S Metals K&S Round Brass Tube: 5/32" OD x 0.014" Wall x 12" Long $1.50

$2.09 -

K&S Metals K&S Round Brass Tube: 5/8" OD x 0.014" Wall x 12" Long $4.99

$6.99 -

K&S Metals K&S Round Brass Tube: 7/16" OD x 0.014" Wall x 12" Long $4.07

$5.69 -

K&S Metals K&S Round Brass Tube: 7/32" OD x 0.014" Wall x 12" Long $1.78

$2.49 -

K&S Metals K&S Round Brass Tube: 9/16" OD x 0.014" Wall x 12" Long $4.28

$5.99 -

K&S Metals K&S Round Brass Tube: 9/32" OD x 0.014" Wall x 12" Long $2.22

$3.09 -

K&S Metals K&S Square Brass Tube: 1/16" OD x 0.014" Wall x 12" Long $2.93

$4.09 -

K&S Metals K&S Square Brass Tube: 1/8" OD x 0.014" Wall x 12" Long $2.57

$3.59 -

K&S Metals K&S Square Brass Tube: 3/32" OD x 0.014" Wall x 12" Long $4.14

$5.79 -

Tichy Train Group Tichy Train .010 Phosphor Bronze Wire (Brass Wire) 1101 $2.25

$3.00 -

Tichy Train Group Tichy Train .0125 Phosphor Bronze Wire (Brass Wire) 1106 $2.25

$3.00 -

Tichy Train Group Tichy Train .015 Phosphor Bronze Wire (Brass Wire) 1102 $2.25

$3.00 -

Tichy Train Group Tichy Train .020 Phosphor Bronze Wire (Brass Wire) 1103 $2.25

$3.00 -

Tichy Train Group Tichy Train .025 Phosphor Bronze Wire (Brass Wire) 1104 $2.25

$3.00 -

Tichy Train Group Tichy Train .040 Phosphor Bronze Wire (Brass Wire) 1107 $2.25

$3.00 -

Trumpeter Trumpeter 20cm Brass Pipe Set 1 - 09942 $4.97

$6.95 -

Trumpeter Trumpeter 20cm Brass Pipe Set 2 - 09943 $4.97

$6.95 -

Trumpeter Trumpeter 20cm Brass Pipe Set 3 - 09944 $4.97

$6.95 -

Trumpeter Trumpeter 20cm Brass Pipe Set 4 - 09945 $4.97

$6.95 -

Trumpeter Trumpeter 20cm Brass Pipe Set 5 - 09946 $4.97

$6.95 -

Trumpeter Trumpeter 20cm Brass Pipe Set 6 - 09947 $4.97

$6.95

Premium Brass Materials for Professional Scale Modeling

Brass represents the material of choice for scale modelers demanding superior strength, authentic metallic appearance, and exceptional workability in detail components and structural applications. This comprehensive collection features precision-engineered brass tubing, rods, and wire from K&S Metals, Tichy Train Group, and Trumpeter, offering round and square tubing in extensive diameter ranges, specialized streamline profiles, bendable fuel tubes, and phosphor bronze wire for applications spanning aircraft detailing, ship rigging, armor modifications, and intricate diorama construction. Whether you're fabricating landing gear for scale aircraft, creating gun barrels for armor models, rigging sailing ships, or adding authentic metal details to dioramas, these brass materials provide the strength, precision, and authentic metallic finish that elevate models from basic assemblies to museum-quality displays.

K&S Round Brass Tube: Comprehensive Diameter Range

K&S Metals round brass tubing provides the foundation for countless modeling applications with an extensive diameter range from delicate 1/16-inch to substantial 5/8-inch outer diameter, all featuring consistent 0.014-inch wall thickness and convenient 12-inch lengths. This graduated sizing allows you to select tubing with minimal waste for specific applications, whether you're fabricating pitot tubes for 1/72 aircraft, gun barrels for 1/35 armor, ship masts for naval models, or structural details for architectural dioramas. The consistent wall thickness across all diameters simplifies calculations for nested tube assemblies and telescoping mechanisms, while the precision manufacturing ensures uniform outer diameters that fit accurately in drilled holes and accept other tubes for slip-fit assemblies. The 12-inch length accommodates most modeling requirements while remaining manageable for storage and handling, providing sufficient material for complete components without requiring spliced joints that compromise both strength and appearance.

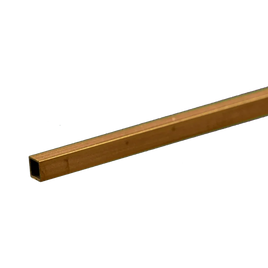

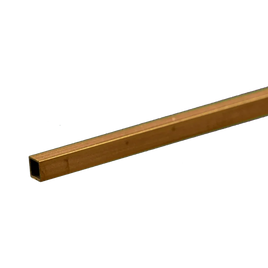

Square Brass Tubing for Structural Applications

K&S square brass tubing offers unique advantages for applications requiring non-circular cross-sections, with sizes including 1/16-inch, 3/32-inch, and 1/8-inch providing options for various scales and structural requirements. Square tubing prevents rotation in assemblies, making it ideal for control linkages, structural frameworks, and mechanical components where rotational stability is essential. The flat surfaces provide superior gluing area compared to round tubing, creating stronger joints with both cyanoacrylate and epoxy adhesives. Square tubing also simplifies alignment during assembly, as the flat sides naturally orient perpendicular to reference surfaces without requiring jigs or fixtures. These properties make square brass tubing valuable for landing gear assemblies, structural reinforcements, architectural details, and any application where the unique characteristics of square cross-sections provide functional or aesthetic advantages over round alternatives.

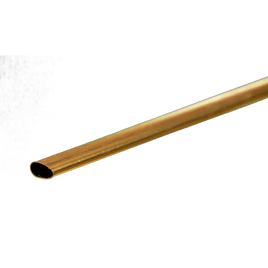

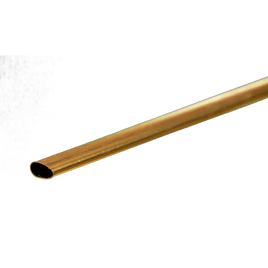

Streamline Brass Tubing for Aerodynamic Applications

K&S streamline brass tubing features an oval cross-section that replicates the aerodynamic profiles used on aircraft struts, landing gear, and external fittings where drag reduction was critical. The 1/4-inch streamline tubing provides authentic detailing for scale aircraft models, particularly vintage and golden-age designs where streamlined components were prominently featured. This specialized profile eliminates the need to fabricate streamlined shapes from round stock, saving time while ensuring accurate cross-sectional geometry. Streamline tubing works perfectly for landing gear struts, external bracing wires, jury struts, and other aircraft components where period-correct streamlining enhances both authenticity and visual appeal. The material's availability in ready-to-use streamline profile demonstrates K&S Metals' understanding of modelers' needs for specialized components that would be impractical to fabricate from basic stock materials.

Bendable Brass Fuel Tube for Flexible Applications

K&S bendable brass fuel tube combines brass's strength and metallic appearance with flexibility that allows routing through complex paths and around obstacles. The 1/8-inch outer diameter with 0.014-inch wall thickness provides adequate strength while remaining flexible enough to bend by hand into smooth curves without kinking or collapsing. This specialized tubing serves perfectly for fuel lines on model engines, hydraulic lines on aircraft and armor models, brake lines on automotive models, and any application requiring flexible metal tubing that maintains its shape after forming. The material accepts soldering for permanent connections, though care must be taken to avoid annealing that would eliminate the temper providing bendability. Bendable brass fuel tube bridges the gap between rigid structural tubing and completely flexible materials like wire, providing the ideal solution for applications requiring both flexibility and tubular form.

Tichy Phosphor Bronze Wire for Rigging and Details

Tichy Train Group phosphor bronze wire provides superior strength and springiness compared to standard brass wire, making it ideal for rigging, antennas, and detail components requiring wire that resists permanent deformation. Available in gauges from delicate .010-inch through robust .040-inch, this wire selection covers applications from fine rigging on sailing ship models to substantial antennas and structural details on larger scales. Phosphor bronze's superior tensile strength allows thinner wire to carry equivalent loads compared to brass, enabling more scale-appropriate rigging diameters on ship models where authentic line thickness is critical for visual accuracy. The material's springiness helps rigging maintain proper tension without sagging, while the slight bronze color provides authentic appearance for period-correct applications. The wire accepts soldering for permanent connections and can be blackened or painted to simulate various materials from steel cables to tarred rigging lines.

Trumpeter Brass Pipe Sets for Comprehensive Coverage

Trumpeter's 20cm brass pipe sets provide curated assortments of tubing sizes designed to cover common modeling requirements without purchasing individual pieces. Sets 1 through 6 offer different diameter ranges and quantities, allowing you to select assortments matching your typical project needs or specific scale requirements. These sets prove especially economical for modelers building multiple projects or maintaining workshop inventories, as the bundled pricing provides value compared to purchasing equivalent quantities of individual tubes. The 20cm (approximately 8-inch) length suits most detail applications while the variety of diameters in each set ensures you have appropriate sizes for nested assemblies, varied detail work, and projects requiring multiple tubing diameters. Trumpeter's sets demonstrate understanding that modelers often need multiple sizes simultaneously, making pre-packaged assortments more convenient than sourcing individual pieces.

Superior Strength for Structural Applications

Brass's mechanical properties provide significantly greater strength compared to aluminum and other non-ferrous metals commonly used in modeling, making it essential for applications where structural integrity under stress is critical. Landing gear components fabricated from brass tubing withstand the impact loads of repeated landings on flying models without bending or failure. Gun barrels and cannon tubes made from brass resist the flexing that causes breakage in plastic alternatives, maintaining alignment and surviving handling incidents. Ship masts and spars constructed from brass tubing support rigging tension without deflection, ensuring models maintain proper geometry. This superior strength allows thinner-walled components that reduce weight while maintaining structural capacity, or alternatively, provides safety margins that prevent failures in critical applications. The material's strength also enables small-diameter components like antenna masts and pitot tubes to survive handling without the constant breakage that plagues plastic alternatives.

Authentic Metallic Finish and Appearance

Brass's natural golden metallic appearance provides authentic visual character that plastic and painted alternatives cannot replicate convincingly. The material's inherent luster captures light realistically, creating the subtle highlights and reflections characteristic of metal components on prototype subjects. Brass accepts polishing to mirror finishes for chrome-like effects on exhaust pipes, engine components, and decorative details, or can be left with natural patina for weathered, service-worn appearances. The material also accepts chemical treatments including blackening solutions that create gun-metal finishes, patina solutions that accelerate aging effects, and various metal colorants that simulate different alloys. This finishing versatility allows brass components to represent everything from polished brass fittings to blackened steel gun barrels, weathered bronze sculptures, or aged copper details, all while maintaining the authentic metallic character that separates professional models from toy-like assemblies.

Excellent Workability with Standard Tools

Despite its superior strength, brass machines and works easily with standard modeling tools and sets, requiring less effort than steel while delivering better results than softer metals. Razor saws and jeweler's saws cut brass tubing cleanly, producing square ends without the crushing that occurs with softer materials. Standard twist drills create precise holes without the grabbing and tearing that plague some metals, while files and sandpaper shape brass smoothly without loading or clogging. Brass also accepts threading for mechanical assemblies, with the material's strength ensuring threads remain functional through repeated assembly cycles. The material solders readily with standard electronics solder and low-temperature silver solders, creating permanent joints stronger than the base material. This workability makes brass accessible to modelers at all skill levels while delivering professional results that justify its premium price compared to plastic alternatives.

Aircraft Detailing Applications

Brass tubing serves countless aircraft detailing applications where strength, authentic appearance, and precise dimensions are essential. Landing gear struts fabricated from appropriately sized brass tubing provide the strength to support model weight while maintaining scale-appropriate diameters impossible with plastic alternatives. Pitot tubes, antenna masts, and gun barrels made from small-diameter brass tubing survive handling without the constant breakage that plagues plastic parts. Exhaust stacks constructed from brass tubing accept realistic weathering and heat-staining effects that enhance authenticity. Control surface hinges, actuator rods, and mechanical linkages benefit from brass's strength and ability to accept soldered joints for permanent, reliable assemblies. These applications demonstrate why serious aircraft modelers maintain comprehensive brass tubing inventories, ensuring appropriate materials are immediately available for detail upgrades and scratch-built components that transform kit-supplied plastic parts into convincing metal replicas.

Ship Modeling and Rigging Applications

Ship modelers rely on brass tubing and wire for masts, spars, rigging, and countless deck details where the material's strength and authentic metallic appearance prove essential. Masts and yards constructed from brass tubing support rigging tension without the deflection that causes sagging in wooden alternatives, while the material's strength allows scale-appropriate diameters that wooden dowels cannot match in small scales. Brass wire serves perfectly for standing and running rigging, with phosphor bronze's superior strength enabling authentic line diameters that maintain proper tension. Deck fittings including cleats, bollards, and fairleads fabricated from brass tubing and rod provide authentic metallic appearance and withstand handling without breakage. Cannon barrels, anchor chains, and decorative railings benefit from brass's workability and finishing characteristics. The material integrates seamlessly with wooden hull construction, accepting both mechanical fastening and adhesive bonding for permanent, reliable assemblies.

Armor and Military Vehicle Detailing

Armor modelers use brass tubing extensively for gun barrels, antenna masts, tow cables, and mechanical details where plastic kit parts lack the strength, precision, or authentic appearance demanded by serious builders. Main gun barrels turned from brass tubing maintain perfect straightness and accept realistic muzzle brake details, bore rifling, and weathering effects impossible with plastic alternatives. Machine gun barrels fabricated from small-diameter brass tubing survive handling while providing scale-appropriate diameters and authentic metallic appearance. Antenna masts made from brass wire resist the permanent bending that plagues plastic parts, maintaining proper geometry through repeated handling. Tow cables and lifting hooks constructed from brass components provide functional strength and authentic weight that enhance realism. These applications explain why competition-level armor models invariably feature brass replacement barrels and detail components that elevate builds beyond out-of-box assemblies.

Diorama and Architectural Applications

Diorama builders and architectural modelers incorporate brass tubing for railings, structural frameworks, utility poles, and countless details where the material's strength, precise dimensions, and metallic appearance enhance realism. Railings and fences constructed from brass tubing and wire maintain geometry without sagging, accept realistic paint finishes, and survive handling without the constant repairs required with plastic alternatives. Utility poles, street lights, and industrial piping fabricated from brass tubing provide authentic scale appearance and structural integrity. Architectural details including handrails, balustrades, and decorative metalwork benefit from brass's workability and finishing characteristics. The material also serves structural purposes, providing hidden frameworks that support scenery elements and ensure dioramas withstand transportation and display without damage. These applications demonstrate brass's versatility beyond traditional modeling subjects, supporting any miniature construction requiring metal components with superior properties.

Nested Tube Assemblies and Telescoping Mechanisms

The extensive diameter range in this collection enables nested tube assemblies where smaller tubes slide inside larger ones, creating telescoping landing gear, retractable antennas, and adjustable support structures. The consistent 0.014-inch wall thickness across K&S tubing simplifies calculations for clearance fits, as each size step provides predictable dimensional relationships. Nested assemblies benefit from brass's strength, as thin-walled tubes resist crushing while maintaining smooth sliding action. The material also accepts soldering for creating stops, collars, and mechanical features that control telescoping action. These assemblies find applications in functional landing gear for flying models, adjustable display stands, and mechanical features on working models. The ability to create reliable nested assemblies from readily available standard tubing demonstrates brass's advantages over materials requiring custom fabrication or specialized components.

Integration with Aluminum and Other Metals

Brass tubing works seamlessly with aluminum tubing and other modeling metals, allowing you to leverage each material's unique properties within single projects. Use brass for high-stress components, visible details requiring authentic metallic appearance, and areas where superior strength justifies the material's higher cost and weight. Employ aluminum for lightweight structural members, hidden frameworks, and applications where weight savings outweigh brass's strength advantages. The materials bond together using mechanical fasteners, epoxy adhesives, or specialized techniques like brazing, creating hybrid assemblies that optimize performance and economy. This multi-material approach allows sophisticated engineering where each component uses the most appropriate material for its specific function, maximizing both structural efficiency and visual authenticity while controlling costs and weight.

Finishing Techniques and Surface Treatments

Brass accepts comprehensive finishing treatments from polished natural metal to painted surfaces simulating various materials and weathering states. For natural brass appearance, progressive polishing with fine abrasives achieves mirror finishes that replicate chrome plating or polished brass fittings. Chemical blackening solutions create gun-metal finishes perfect for gun barrels, exhaust pipes, and steel components. Patina solutions accelerate natural aging, creating verdigris effects on copper and bronze details. Brass also accepts paint readily after proper surface preparation with primer, allowing you to simulate any material from painted steel to anodized aluminum. Weathering techniques including dry brushing, washes, and pigments create realistic wear patterns, rust streaks, and service grime. This finishing versatility makes brass adaptable to any modeling aesthetic while maintaining the authentic metallic character that justifies its selection over plastic alternatives.

Trusted Manufacturers with Proven Quality

K&S Metals has manufactured precision metal products for hobbyists and professionals since 1950, establishing quality standards that define the industry. Their brass tubing features consistent dimensions, straight true pieces, and material properties that ensure reliable performance. Tichy Train Group specializes in model railroad details with phosphor bronze wire that meets the demanding requirements of fine-scale rigging and detail work. Trumpeter leverages their extensive modeling experience to provide curated brass pipe sets addressing common modeling needs. These manufacturers maintain strict quality control ensuring materials perform predictably and deliver professional results that justify brass's premium price compared to plastic alternatives.