-

Bud Nosen Bud Nosen Birch Aircraft Plywood 1/32" x 12" x 12" 3ply (6/pkg) 6225 $33.75

$45.00 -

Bud Nosen Bud Nosen Birch Aircraft Plywood 1/4" x 12" x 12" 5ply (6/pkg) 6285 $40.28

$53.70 -

Bud Nosen Bud Nosen Birch Aircraft Plywood 1/64" x 12" x 12" 3ply (6/pkg) 6215 $63.00

$84.00 -

Bud Nosen Bud Nosen Birch Aircraft Plywood 1/8" x 6" x 12" 5ply (6/pkg) 6267 $34.88

$46.50 -

Bud Nosen Bud Nosen Birch Aircraft Plywood 3/32" x 12" x 24" 5ply (6/pkg) 6243 $132.75

$177.00 -

Bud Nosen Bud Nosen Birch Aircraft Plywood 3/8" x 12" x 24" 7ply (6/pkg) 6293 $77.63

$103.50 -

Bud Nosen Bud Nosen Birch Plywood 1/16" x 12" x 12" 3 Ply (6/pkg) 6235 $38.25

$51.00 -

Bud Nosen Bud Nosen Birch Plywood 1/16" x 12" x 24" 3 Ply (6/pkg) 6233 $76.50

$102.00 -

Bud Nosen Bud Nosen Birch Plywood 1/16" x 6" x 12" 3 Ply (6/pkg) 6237 $19.13

$25.50 -

Bud Nosen Bud Nosen Birch Plywood 1/32" x 12" x 24" 3 Ply (6/pkg) 6223 $67.50

$90.00 -

Bud Nosen Bud Nosen Birch Plywood 1/32" x 6" x 12" 3 Ply (6/pkg) 6227 $17.52

$23.35 -

Bud Nosen Bud Nosen Birch Plywood 1/4" x 12" x 24" 5 Ply (6/pkg) 6283 $78.75

$105.00 -

Bud Nosen Bud Nosen Birch Plywood 1/4" x 6" x 12" 5 Ply (6/pkg) 6287 $20.25

$27.00 -

Bud Nosen Bud Nosen Birch Plywood 1/64" x 12" x 24" (3 Ply) 6213 $126.00

$168.00 -

Bud Nosen Bud Nosen Birch Plywood 1/64" x 6" x 12" 3 Ply (6/pkg) 6217 $32.63

$43.50 -

Bud Nosen Bud Nosen Birch Plywood 1/8" x 12" x 12" 3 Ply (6/pkg) 6255 $28.32

$37.74 -

Bud Nosen Bud Nosen Birch Plywood 1/8" x 12" x 12" 5 Ply (6/pkg) 6265 $66.38

$88.50 -

Bud Nosen Bud Nosen Birch Plywood 1/8" x 12" x 24" 3 Ply (6/pkg) 6253 $56.25

$75.00 -

Bud Nosen Bud Nosen Birch Plywood 1/8" x 12" x 24" 5 Ply (6/pkg) 6263 $132.75

$177.00 -

Bud Nosen Bud Nosen Birch Plywood 1/8" x 6" x 12" 3 Ply (6/pkg) 6257 $14.18

$18.90 -

Bud Nosen Bud Nosen Birch Plywood 3/16" x 12" x 12" 4 Ply (6/pkg) 6275 $34.88

$46.50 -

Bud Nosen Bud Nosen Birch Plywood 3/16" x 12" x 24" 4 Ply (6/pkg) 6273 $69.75

$93.00 -

Bud Nosen Bud Nosen Birch Plywood 3/16" x 6" x 12" 4 Ply (6/pkg) 6277 $17.52

$23.34 -

Bud Nosen Bud Nosen Birch Plywood 3/32" x 12" x 12" 5 Ply (6/pkg) 6245 $67.28

$89.70 -

Bud Nosen Bud Nosen Birch Wood Dowels 1" x 36" (3/pkg) 5421 $32.63

$43.50 -

Bud Nosen Bud Nosen Birch Wood Dowels 1-1/8" x 36" (3/pkg) 5423 $34.32

$45.75 -

Bud Nosen Bud Nosen Birch Wood Dowels 1/2" x 36" (12/pkg) 5413 $29.25

$39.00 -

Bud Nosen Bud Nosen Birch Wood Dowels 1/4" x 36" (30/pkg) 5405 $24.53

$32.70 -

Bud Nosen Bud Nosen Birch Wood Dowels 1/8" x 36" (45/pkg) 5401 $20.25

$27.00 -

Bud Nosen Bud Nosen Birch Wood Dowels 3/16" x 36" (36/pkg) 5403 $21.34

$28.44 -

Bud Nosen Bud Nosen Birch Wood Dowels 3/4" x 36" (6/pkg) 5417 $37.13

$49.50 -

Bud Nosen Bud Nosen Birch Wood Dowels 5/8" x 36" (10/pkg) 5415 $39.38

$52.50 -

Bud Nosen Bud Nosen Birch Wood Dowels 7/16" x 36" (12/pkg) 5411 $27.00

$36.00 -

Bud Nosen Bud Nosen Birch Wood Dowels 7/8" x 36" (4/pkg) 5419 $35.85

$47.80 -

Bud Nosen Bud Nosen Wood Dowels 3/8" x 36" (20/pkg) 5409 $30.00

$40.00 -

Bud Nosen Bud Nosen Wood Dowels 5/16" x 36" (25/pkg) 5407 $26.25

$35.00

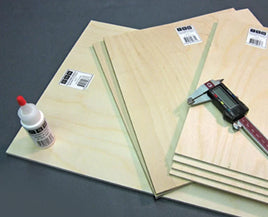

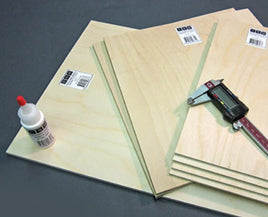

Premium Finnish Birch Plywood and Dowels for Aircraft Construction

Finnish birch plywood represents the gold standard for aircraft-grade wood materials, combining exceptional strength-to-weight ratio, superior dimensional stability, and consistent quality that has made it the preferred choice for model aircraft builders and precision woodworkers for generations. This comprehensive collection features Bud Nosen birch aircraft plywood in thicknesses ranging from ultra-thin 1/64 inch to substantial 3/8 inch, with ply counts from 3-ply to 7-ply construction, plus precision-manufactured birch dowels spanning 1/8 inch to 1-1/8 inch diameter. Sourced from Finland's carefully managed forests where slow growth produces dense, fine-grained wood, these materials deliver the structural integrity, workability, and reliability essential for wood aircraft construction, high-stress structural applications, and fine woodworking projects where material performance directly impacts success.

Aircraft-Grade Plywood: Engineered for Performance

Aircraft plywood differs fundamentally from standard plywood through stricter manufacturing standards, superior veneer selection, and specialized adhesives that create materials capable of withstanding the stresses of flight and structural loading. Bud Nosen birch aircraft plywood features carefully selected veneers with straight, uniform grain oriented for maximum strength, bonded with waterproof phenolic resin adhesives that maintain integrity under temperature extremes and humidity variations. The manufacturing process ensures void-free construction with consistent thickness throughout each sheet, eliminating the weak spots and thickness variations that plague lower-grade plywoods. Each ply is precisely calibrated to contribute to overall strength, with cross-grain orientation that provides equal strength in both directions while minimizing warping and dimensional changes. This engineering excellence makes aircraft plywood essential for wing ribs, fuselage formers, control surfaces, and any application where structural failure is unacceptable.

Comprehensive Thickness Range for Every Application

The extensive thickness selection in this collection ensures you can select birch plywood with optimal strength and weight characteristics for each specific application. Ultra-thin 1/64-inch plywood serves perfectly for lightweight wing ribs on indoor models, delicate formers, and applications where minimizing weight is paramount. The 1/32-inch thickness provides increased strength while remaining suitable for small-scale aircraft and weight-sensitive components. Mid-range thicknesses including 1/16-inch and 3/32-inch represent versatile choices for general aircraft construction, offering excellent strength-to-weight ratios for wing ribs, fuselage sides, and structural bulkheads. Heavier sheets like 1/8-inch, 3/16-inch, and 1/4-inch deliver the rigidity needed for motor mounts, landing gear plates, and high-stress structural components. The substantial 3/8-inch plywood provides maximum strength for firewall applications, main wing spars, and areas subjected to extreme loading. This graduated sizing allows you to engineer aircraft structures with appropriate material thickness for each component's specific loading conditions.

Multi-Ply Construction for Superior Strength

The ply count in birch plywood directly impacts strength, stiffness, and dimensional stability, with higher ply counts generally providing superior performance characteristics. Three-ply construction offers the minimum viable structure for aircraft applications, with face veneers and a core layer providing basic cross-grain strength. Five-ply plywood adds intermediate layers that significantly increase stiffness and impact resistance, making it the preferred choice for most aircraft structural components. Seven-ply construction in the thickest sheets delivers maximum strength and dimensional stability for critical applications like firewalls and main structural members. The odd number of plies ensures balanced construction with equal numbers of cross-grain layers on each side of the center ply, preventing warping and maintaining flatness. Each additional ply increases material cost and weight but delivers proportionally greater strength and reliability, allowing you to select appropriate ply counts based on structural requirements and weight budgets.

Finnish Birch: Superior Material Properties

Finland's northern climate produces birch with exceptional properties for aircraft construction and precision woodworking. The slow growth rates in cold climates create dense wood with tight grain spacing and minimal variation between early and late growth rings, resulting in uniform strength characteristics throughout each sheet. Finnish birch exhibits superior hardness compared to birch from warmer climates, providing better screw-holding, improved impact resistance, and enhanced durability under service conditions. The fine, uniform grain machines cleanly without tear-out, accepts adhesives evenly for strong glue joints, and finishes smoothly with minimal surface preparation. Finnish birch also demonstrates excellent dimensional stability, resisting warping, twisting, and dimensional changes caused by humidity fluctuations that plague woods from less stable species. These superior material properties justify Finnish birch's premium price and explain why serious aircraft builders specify Finnish birch rather than accepting substitutes from other sources or species.

Precision Birch Dowels for Structural Applications

Birch dowels provide ready-to-use round stock for applications requiring cylindrical components with precise, consistent diameters. The collection includes dowels from delicate 1/8-inch diameter suitable for control linkages and small structural members, through mid-range sizes like 1/4-inch, 3/8-inch, and 1/2-inch for general structural applications, to substantial 1-inch and 1-1/8-inch diameters for main wing spars and primary load-bearing members. Each dowel is precision-manufactured to tight diameter tolerances ensuring consistent fit in drilled holes and uniform strength characteristics. The 36-inch length accommodates most aircraft wingspans and structural requirements without requiring spliced joints that compromise strength. Birch dowels offer superior strength compared to softer woods, making them ideal for wing spars, fuselage longerons, landing gear struts, and any application where structural loading demands hardwood properties. The smooth, straight dowels also serve non-structural purposes including control surface hinges, alignment pins, and decorative details.

Sheet Sizes for Efficient Material Utilization

Bud Nosen birch plywood is available in multiple sheet sizes that balance material efficiency with practical handling and storage considerations. The 6-inch by 12-inch size provides economical material for small projects, test pieces, and applications requiring limited quantities. The 12-inch by 12-inch format offers versatility for medium-sized components while remaining manageable for cutting and handling. The 12-inch by 24-inch sheets deliver the most economical material utilization for larger projects, reducing waste and providing sufficient dimensions for wing panels, fuselage sides, and other major components. The multi-piece packaging (typically 6 sheets per package) ensures you have adequate material for complete projects while offering value compared to purchasing individual sheets. Consider your project's component sizes when selecting sheet dimensions, as choosing appropriately sized sheets minimizes cutting waste and reduces material costs.

Superior Workability with Precision Tools

Despite its hardwood classification and aircraft-grade strength, birch plywood machines and works with exceptional ease using standard modeling tools and sets. Sharp hobby knives cut thin plywood cleanly, though thicker sheets benefit from razor saws or jeweler's saws for straight, accurate cuts. The material accepts drilling without splintering when proper techniques are used, creating clean holes for dowel joints, fasteners, and alignment pins. Birch plywood sands smoothly with fine-grit papers, achieving excellent surface finishes for painting or clear coating. The material also accepts edge treatments including beveling, rounding, and chamfering that enhance both appearance and aerodynamic performance. Birch plywood glues reliably with both aliphatic resin wood glues and cyanoacrylate adhesives, creating joints that often prove stronger than the surrounding wood. This workability makes birch plywood accessible to builders at all skill levels while delivering professional results that justify its premium price.

Laser Cutting and CNC Machining Capabilities

Birch plywood's uniform density, consistent thickness, and fine grain make it ideal for laser cutting and CNC machining applications where precision and clean edges are essential. The material cuts cleanly with minimal charring, producing sharp edges and fine details that require little post-processing. Unlike resinous woods that produce excessive smoke or adhesive-heavy plywoods that gum up cutting tools, birch plywood machines predictably with consistent cutting characteristics. The void-free construction ensures uniform cutting speeds across entire sheets, preventing the variable results that occur with lower-grade plywoods containing gaps and density variations. Laser-cut birch components fit together precisely, as the material's dimensional stability prevents warping after cutting. This machining excellence makes birch plywood the preferred material for complex wing ribs, intricate formers, and any components where computer-controlled cutting delivers complexity and precision beyond hand-cutting capabilities.

Aircraft Construction Applications

Birch plywood serves countless critical applications in model aircraft construction where strength, reliability, and dimensional stability are essential. Wing ribs cut from appropriate thickness plywood provide the structural framework that defines airfoil shape and supports wing covering, with the material's strength allowing thin, lightweight ribs that minimize wing weight. Fuselage formers and bulkheads maintain fuselage cross-section while providing mounting points for longerons, stringers, and equipment. Firewalls fabricated from thick, multi-ply birch plywood protect wooden structures from engine heat while providing robust mounting for engines and motor mounts. Control surface components including elevator and rudder structures benefit from birch plywood's strength and light weight. Landing gear plates and motor mounts require birch plywood's ability to withstand concentrated loads and vibration without failure. These applications demonstrate why serious aircraft builders invest in premium Finnish birch plywood rather than accepting compromises with inferior materials.

Structural Framework and Load-Bearing Applications

Beyond aircraft construction, birch plywood and dowels serve any modeling application requiring superior strength and dimensional stability. Architectural models benefit from birch plywood's ability to maintain precise dimensions and resist warping, ensuring models accurately represent designs. Diorama bases and structural frameworks built from birch plywood provide stable foundations that support scenery and figures without sagging or distortion. Furniture construction for dollhouses and miniature room settings requires birch plywood's fine grain and strength for creating convincing scaled furnishings. Birch dowels serve as structural members in countless applications from ship masts to architectural columns, providing cylindrical components with consistent dimensions and superior strength. The material's reliability makes it essential for any project where structural failure would compromise months of work or create safety concerns in flying models.

Finishing and Surface Treatment Options

Birch plywood accepts comprehensive finishing treatments from natural wood finishes to opaque paints, providing versatility for any modeling aesthetic. For natural wood appearances, birch's attractive grain patterns and light color create appealing surfaces when treated with clear finishes including lacquer, varnish, or polyurethane. The fine grain accepts stains evenly, allowing you to simulate darker woods while maintaining birch's superior structural properties. For painted finishes, birch plywood's smooth surface requires minimal preparation beyond light sanding and priming, accepting both brush-applied and airbrushed paints with excellent results. The material also accepts specialized aircraft finishes including tissue covering with dope, heat-shrink films, and fiberglass cloth for applications requiring lightweight, durable skins. Birch plywood's ability to accept these varied finishing treatments makes it adaptable to any modeling aesthetic while maintaining the structural performance that justifies its selection.

Bud Nosen: Trusted Quality Since 1954

Bud Nosen Models has supplied premium modeling materials to the aircraft building community since 1954, earning recognition for consistent quality and reliable performance. Their birch plywood undergoes rigorous quality control ensuring materials meet aircraft-grade standards for void-free construction, proper adhesive bonding, and accurate thickness. The company's long-standing relationships with Finnish suppliers ensure access to premium birch from carefully managed forests, maintaining the superior material properties that distinguish Finnish birch from alternatives. Bud Nosen's commitment to quality means you receive straight, flat sheets free from warps, delamination, and thickness variations that compromise construction quality. This reliability allows you to purchase birch plywood with confidence, knowing materials will perform as expected and deliver the structural integrity your projects demand.

Material Selection and Project Planning

Successful birch plywood selection requires matching material thickness and ply count to your project's specific structural requirements and weight constraints. Flying model aircraft demand careful attention to strength-to-weight ratios, using the thinnest plywood that provides adequate strength for each application. Static display models allow greater flexibility, as weight becomes less critical than appearance and dimensional stability. Calculate material requirements by measuring component dimensions and adding allowances for cutting waste, test pieces, and construction errors. Birch plywood's premium price justifies careful material planning to minimize waste, though having extra material prevents frustrating mid-project shortages. Consider purchasing multiple thicknesses even if plans specify specific dimensions, as having material options during construction allows you to optimize each component's properties based on actual structural requirements and weight budgets.

Integration with Other Modeling Woods

Birch plywood works seamlessly with other craft wood materials including balsa and basswood, allowing you to leverage each material's unique properties within single projects. Use birch plywood for high-stress structural components like wing ribs, firewalls, and landing gear plates, while employing balsa for secondary structures and built-up frameworks where weight savings matter more than maximum strength. Combine birch plywood with basswood for applications requiring fine surface detail and smooth finishes. Birch dowels integrate with balsa and basswood sticks to create hybrid structures optimizing both strength and weight. These materials bond together effectively using standard wood glues, creating strong joints that integrate different woods into unified structures. This multi-material approach allows you to engineer projects with optimal material selection for each component's specific function, maximizing performance while controlling weight and cost.

Storage and Handling Best Practices

Proper birch plywood storage preserves material quality and prevents warping that compromises construction accuracy. Store sheets flat on level surfaces, avoiding leaning that creates permanent warps. Keep plywood in sealed plastic bags or containers to prevent moisture absorption and dimensional changes, maintaining the stable moisture content established during manufacturing. Store different thicknesses separately with clear labeling for easy identification during projects. Keep plywood away from heat sources and direct sunlight that can cause warping and adhesive degradation. Handle sheets carefully to prevent edge damage and delamination, supporting full sheet dimensions rather than allowing unsupported areas to flex. Birch dowels should be stored horizontally on supports preventing sagging, kept straight to maintain their precision-manufactured dimensions. These storage practices ensure your birch materials remain in perfect condition for years, ready for use whenever projects demand premium aircraft-grade wood materials.